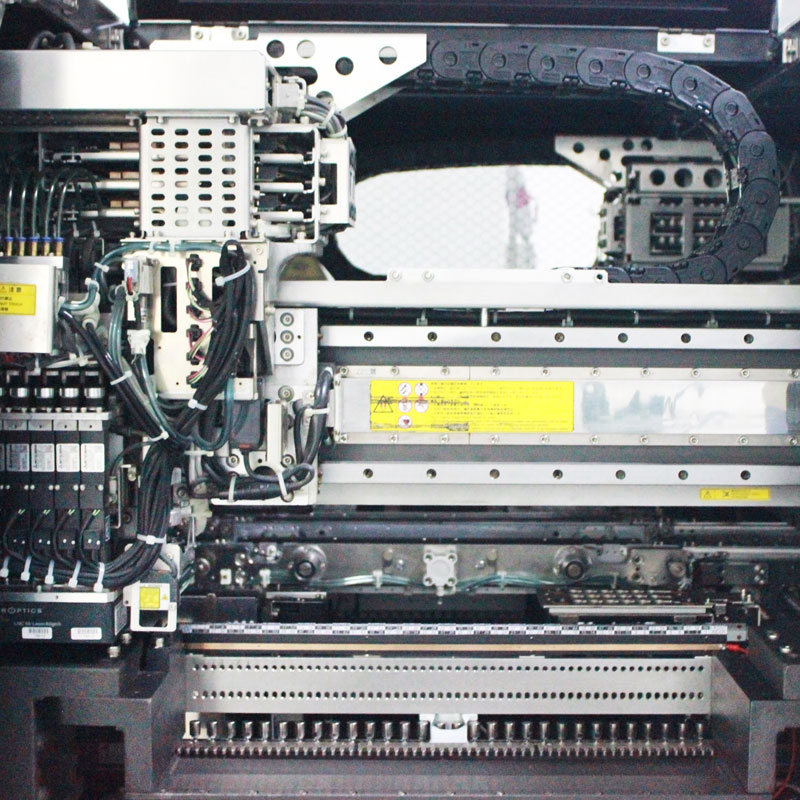

FX-3RL JUKI SMT Chip mounter

FX-3RL JUKI SMT Chip mounter

FX-3RL JUKI SMT Chip Mounter – High-Speed Precision Pick and Place Machine

The FX-3RL JUKI SMT Chip Mounter is a state-of-the-art Surface Mount Technology (SMT) machine engineered for high-speed and precise placement of a wide variety of electronic components. Known for its reliability, efficiency, and flexibility, the FX-3RL is a powerful solution for modern electronics manufacturing, especially in high-volume assembly lines. Whether you’re assembling consumer electronics, automotive components, or medical devices, the FX-3RL ensures optimal performance for both small and large-scale production.

At Motobotix, we offer fully refurbished and certified used FX-3RL JUKI SMT Chip Mounters that have undergone extensive testing to ensure they perform like new. Our refurbished equipment provides manufacturers with the opportunity to access high-performance machines at a fraction of the cost of brand-new equipment.

Key Features of the FX-3RL JUKI SMT Chip Mounter

The FX-3RL JUKI SMT Chip Mounter is packed with advanced features that make it one of the top choices for manufacturers in need of speed, accuracy, and versatility. Here are some of its key features:

1. High-Speed Placement Capability

The FX-3RL offers high-speed placement capabilities of up to 60,000 components per hour (CPH), making it perfect for high-volume production environments. Its exceptional speed ensures that production cycles are optimized, allowing manufacturers to meet tight deadlines and improve throughput. Whether you’re assembling resistors, capacitors, QFNs, or BGAs, the FX-3RL can handle large production runs without compromising quality or performance.

2. Outstanding Placement Accuracy

With a placement accuracy of ±0.02mm, the FX-3RL ensures precise placement of components, even for the most delicate and small components such as 0201 packages. The high-resolution vision system automatically adjusts for misalignment and guarantees that each component is positioned correctly on the PCB. This ensures reliable and accurate assembly of components, reducing the chances of defects and minimizing the need for costly rework.

3. Wide Range of Component Handling

The FX-3RL JUKI SMT Chip Mounter is designed to handle a wide variety of component sizes and types, making it a versatile choice for diverse electronics manufacturing needs. From small chip components like resistors and capacitors to larger ICs and BGAs, the FX-3RL adapts effortlessly to different production requirements. Its flexibility ensures manufacturers can produce a broad range of products without the need for multiple machines, making it a highly cost-effective option.

4. Advanced Vision System for Accuracy and Alignment

Equipped with a cutting-edge vision system, the FX-3RL guarantees real-time component alignment and adjustment for accuracy during placement. This system enhances placement precision and allows for automatic correction of misaligned components. In addition, the vision system performs automated inspection of placed components, detecting any misplacement or defects and helping prevent costly assembly errors.

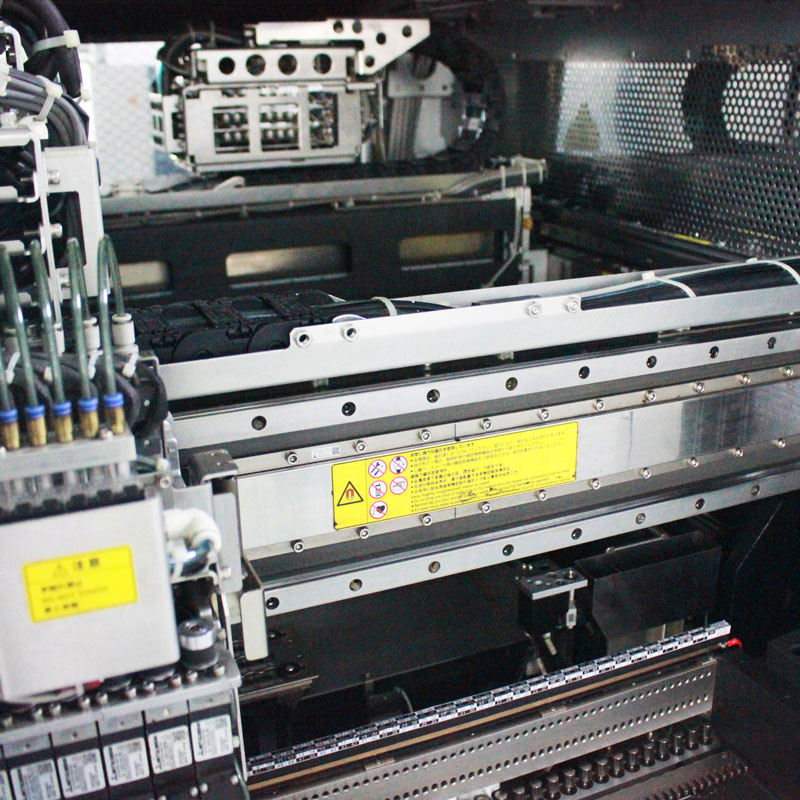

5. High Flexibility with Feeder Configuration

The FX-3RL supports a variety of feeder configurations, accommodating up to 120 feeders for continuous production. The machine’s flexible feeder system allows quick reconfiguration, enabling operators to easily switch between different components and reduce downtime during setup changes. The ability to accommodate multiple feeders simultaneously ensures that the machine operates efficiently and continuously, maximizing productivity.

6. Dual Gantry Design for Improved Throughput

The dual gantry design of the FX-3RL further enhances its throughput by allowing simultaneous placement on both sides of the PCB. This feature significantly reduces cycle times and increases overall production efficiency, especially for multi-layered PCBs or complex assemblies that require dual-sided placement.

7. User-Friendly Interface

The FX-3RL JUKI SMT Chip Mounter features an intuitive touchscreen interface that makes machine operation and monitoring effortless. With easy-to-navigate controls and real-time performance data, operators can quickly adjust settings, troubleshoot issues, and optimize production without the need for extensive training. This user-friendly design reduces the learning curve and boosts operator efficiency.

8. Low Maintenance and High Durability

JUKI’s reputation for durability and reliability is evident in the FX-3RL, which is designed for long-term performance in demanding production environments. The machine’s modular design makes it easy to maintain and service, reducing downtime and enhancing machine uptime. Regular maintenance can be performed with minimal disruption to production, ensuring a consistent and reliable operation.

Applications of the FX-3RL JUKI SMT Chip Mounter

The FX-3RL is highly versatile and can be used across various industries that require precision and high-volume production. Here are some key applications of the FX-3RL:

1. Consumer Electronics Manufacturing

In the consumer electronics industry, the FX-3RL excels at assembling small, high-density components used in products such as smartphones, tablets, and wearable devices. The high-speed and precise placement capabilities make it a perfect fit for producing the next generation of consumer electronics with small, intricate parts.

2. Automotive Electronics

The automotive electronics industry relies on high-quality and high-performance components for applications like infotainment systems, safety sensors, and engine control units (ECUs). The FX-3RL is well-equipped to handle these components with precision, ensuring the quality and functionality of automotive electronics used in modern vehicles.

3. Medical Devices Manufacturing

The FX-3RL is also ideal for the medical device manufacturing industry, where precision and reliability are paramount. The machine’s accurate placement and ability to handle small, delicate components make it well-suited for the production of diagnostic equipment, implantable devices, and other critical medical components that require high standards of quality and accuracy.

4. Industrial Electronics

The FX-3RL is used in industrial electronics for assembling components in systems like automation controls, sensors, and robotics. Its ability to handle various component types, including larger parts, makes it an essential tool for manufacturers in the industrial sector.

Looking for the FX-3RL JUKI SMT Chip Mounter in New Delhi or Across India?

If you’re looking for a SMT machine for sale in New Delhi or anywhere across India, Motobotix provides fully refurbished and certified used equipment, including the FX-3RL JUKI SMT Chip Mounter. Our refurbished machines go through extensive testing to ensure they meet the highest standards of performance and reliability. We deliver cost-effective SMT solutions that meet your production needs, helping you maximize efficiency without breaking your budget.