M1 Plus SMT Equipment Chip Mounter

M1 Plus SMT Equipment Chip Mounter

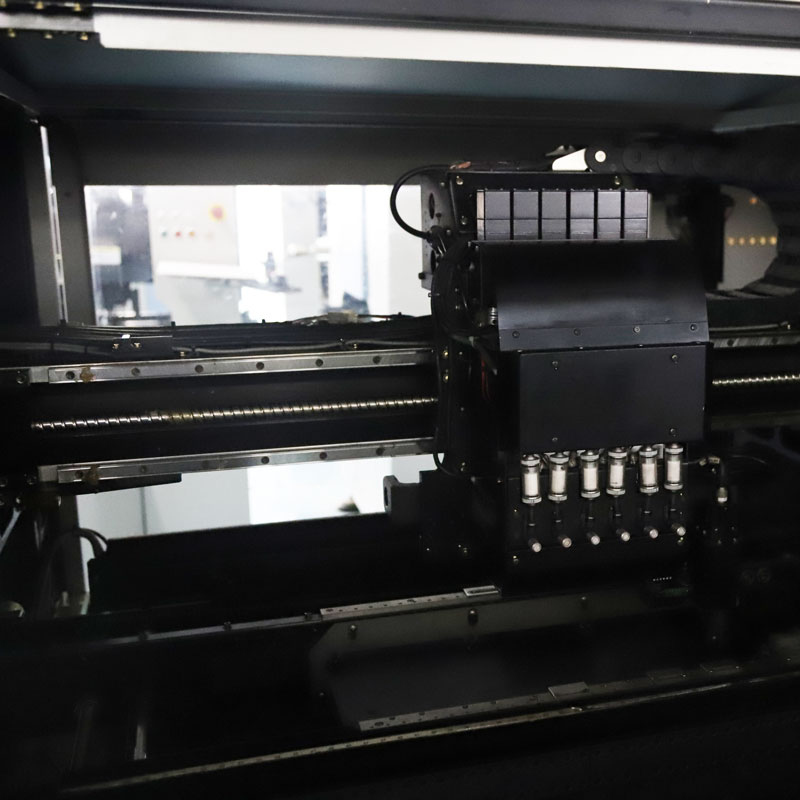

M1 Plus SMT Equipment Chip Mounter – High Speed Precision Pick and Place Solution

The M1 Plus SMT Chip Mounter is an advanced Surface Mount Technology (SMT) machine designed to deliver high-speed placement and exceptional precision for a wide range of electronic manufacturing applications. Known for its reliability, flexibility, and high performance, the M1 Plus smt equipment chip mounter is an ideal choice for manufacturers seeking to optimize their production processes with a cost-effective solution that doesn’t compromise on quality. Whether you’re working with small components for consumer electronics or larger parts for industrial electronics, the M1 Plus provides the perfect balance of speed and accuracy to meet the demands of modern PCB assembly lines.

At Motobotix, we offer fully refurbished and certified used M1 Plus machines that are thoroughly tested to ensure top-notch performance. Our used machines deliver outstanding value without sacrificing the quality and reliability needed for efficient, high-volume production. This enables manufacturers to benefit from top-tier SMT equipment while maintaining cost-effectiveness.

Key Features of the M1 Plus SMT Chip Mounter

The M1 Plus Chip Mounter is built with a host of advanced features designed to improve placement accuracy, speed, and flexibility. Below are some of the key features that set the M1 Plus apart from other pick and place machines:

1. High Speed Performance

One of the standout features of the M1 Plus is its high-speed placement capabilities. This machine is capable of placing up to 30,000 components per hour (CPH), making it an ideal solution for high-volume production environments where efficiency and throughput are critical. The ability to place a large number of components quickly helps to minimize production downtime, enabling manufacturers to meet tight production deadlines.

2. Exceptional Placement Accuracy

Precision is critical in the electronics manufacturing process, and the M1 Plus smt equipment chip mounter excels in this area. With a placement accuracy of ±0.02mm, the M1 Plus ensures that even the most delicate and small components, such as 0201 resistors, QFNs, and BGAs, are accurately placed onto the PCB. This level of accuracy reduces the risk of defects and costly rework, ensuring high-quality assembly.

The machine’s vision system is capable of performing real-time alignment and inspection, automatically adjusting for any misalignment, ensuring each component is correctly placed on the board. This technology is essential for maintaining quality control in high-precision applications.

3. Versatility in Handling Components

The M1 Plus is designed to accommodate a wide variety of component types and sizes, including both small SMD components and larger ICs and BGAs. This versatility allows the machine to be used for different kinds of projects, from consumer electronics to automotive electronics and industrial devices.

Its ability to handle components ranging from tiny chip resistors to large, complex ICs makes it suitable for various industries that require both flexibility and precision in their assembly processes. Whether you’re producing smartphones, medical devices, or automotive electronics, the M1 Plus provides the needed flexibility to meet different production requirements.

4. Efficient Feeder System

The M1 Plus is equipped with a highly efficient feeder system, which can accommodate a wide range of feeders. With the ability to handle up to 120 feeders, the system allows for continuous operation with minimal interruptions for component changes. This helps reduce downtime, increase operational efficiency, and streamline production processes.

Additionally, the quick-change feeder system makes it easy to switch between different components, ensuring that the machine can be rapidly reconfigured for different production runs. This feature significantly improves the flexibility and speed of the machine.

5. Dual Gantry Design for Increased Throughput

The M1 Plus features a dual gantry system, which enhances throughput by allowing the machine to place components on both sides of the PCB simultaneously. This dual gantry design reduces cycle times, improving the overall speed of the production process.

The ability to work on both sides of the PCB without requiring additional machines helps manufacturers save time, reduce costs, and simplify the assembly process. It is particularly beneficial for multi-layered or larger PCBs that require dual-sided assembly.

6. Advanced Vision System for Alignment and Inspection

The M1 Plus is equipped with an advanced vision system that ensures the highest level of precision during the component placement process. This system uses high-resolution cameras to detect misalignment and adjust placements in real-time, significantly reducing the risk of defects.

In addition to its alignment capabilities, the vision system also conducts automated inspection to check for misplaced components or defects during the assembly process. This technology ensures that the final product meets high-quality standards without requiring manual intervention.

7. User Friendly Interface

The M1 Plus comes with an intuitive touchscreen interface that simplifies machine operation. The easy-to-use controls allow operators to quickly set up the machine, configure placement settings, and monitor the machine’s performance in real-time. This user-friendly interface reduces the learning curve for new operators and improves overall productivity.

The M1 Plus also features automated programming capabilities, reducing the time required for setup and enabling quick adaptation to changing production requirements. With minimal manual programming, operators can spend more time focusing on production and less time on machine configuration.

8. Low Maintenance and High Durability

The M1 Plus is built with durability in mind, ensuring that it remains operational for extended periods without requiring frequent maintenance. Its modular design allows for easy access to components for routine maintenance or repairs, minimizing downtime.

The machine’s design is optimized for long-term performance in demanding production environments. With the right care, the M1 Plus can continue to deliver reliable service for many years, providing manufacturers with a high return on investment (ROI).

Applications of the M1 Plus Chip Mounter

The M1 Plus is highly versatile and can be used in a wide range of industries that require efficient and precise SMT assembly. Some of the key applications for the M1 Plus include:

1. Consumer Electronics

In the consumer electronics industry, the M1 Plus is ideal for assembling complex, small components used in devices such as smartphones, tablets, and wearables. Its high-speed performance and precision placement ensure that electronics manufacturers can meet tight production deadlines while maintaining the highest quality standards.

2. Automotive Electronics

The M1 Plus is well-suited for automotive electronics, where components are used in critical systems such as infotainment systems, sensors, and engine control units (ECUs). The machine’s high precision and speed help manufacturers deliver reliable automotive products that perform well under demanding conditions.

3. Medical Device Manufacturing

In the medical device industry, precision and reliability are crucial. The M1 Plus is used to assemble diagnostic equipment, surgical instruments, and implantable devices, ensuring that each component is placed accurately to meet the highest medical standards.

4. Industrial Electronics

The M1 Plus is also used in the industrial electronics sector for assembling components used in automation systems, robotics, and sensors. The machine’s ability to handle a wide range of component sizes and types makes it an excellent choice for industrial applications where quality and reliability are critical.

Looking for an M1 Plus SMT Machine in New Delhi or Across India?

If you’re looking for a SMT machine for sale in New Delhi or anywhere across India, Motobotix offers fully refurbished and certified used equipment, including the used M1 Plus Chip Mounter. We specialize in delivering cost-effective SMT solutions that meet your production needs. Our refurbished machines undergo rigorous testing to ensure that they perform like new, providing manufacturers with the reliability and performance required to stay competitive.

At Motobotix, we are committed to providing top-quality SMT equipment that will enhance your manufacturing processes, reduce costs, and boost productivity.

M1 Plus SMT Equipment Chip Mounter

The M1 Plus SMT Chip Mounter is a high-speed, flexible, and precise pick and place machine that offers exceptional value for a wide range of electronics manufacturing applications. With features like high-speed placement, exceptional placement accuracy, and a dual gantry design, the M1 Plus is engineered to meet the demands of modern production lines. Whether you’re working in consumer electronics, automotive, or medical device manufacturing, the M1 Plus provides the speed, flexibility, and precision required to maintain a competitive edge in the marketplace.

For those seeking affordable SMT equipment, Motobotix offers fully tested and certified refurbished M1 Plus machines, ensuring optimal performance without breaking your budget. Enhance your manufacturing process, reduce costs, and increase productivity with the M1 Plus Chip Mounter.